Magnutom-5000

- Intuitive icon-based programming

- Simulator function

- AxioWash automatic cleaning

As the only cut-off machine in its field, Magnutom-5000 can map out the most complex of section sequences and simulate all individ...

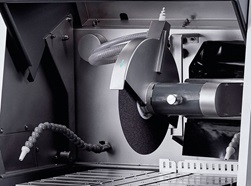

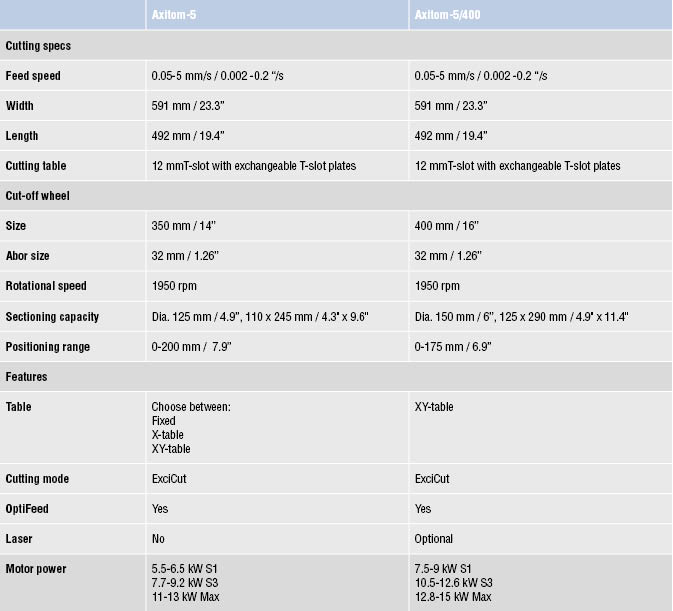

If you visit some of the largest automotive materialographic facilities around the world, there is a good chance that you will come across the Axitom fully automatic cutting machine. One of the reasons for this is the fact that Axitom meets the very specific demands which the automotive industry makes regarding workpiece sizes, complex shapes, and serial cuts. A very large cutting chamber, automatic tables, and movement in X, Y, and Z directions allows for positioning, clamping, and sectioning of both large, complex, and irregular workpieces. Axitom is available in two models and multiple versions, and throughout this webpage the full-featured model is displayed. Get an overview of all versions at the bottom of this page.

Along with Axitom’s powerful motor, the overload protection, and the OptiFeed intelligent feed control protects you from motor overload. The valuable information from the mileage monitoring together with the AxioWash automatic cleaning ensures you maximum uptime of Axitom’s fully automatic cutting machine and the extension of the total lifetime of the machine.

The cutting table in Axitom measures 591 x 492 mm (23.3” x 19.4”), and on top of that, with the two automatic tables, a movement of 100 mm (4.0”) in X-direction and 150 mm (5.9”) in Y-direction can be added. This allows for positioning, clamping, and sectioning of very large and irregular workpieces in Axitom. In addition, a large space underneath the cut-off wheel allows for very high workpieces up to 200 mm (8.0”) to be clamped.

All functions are controlled by only two control units, the three-axes joystick and the multifunction knob, making operation extremely user-friendly. The joystick is very robust, designed for production environments and industrial production. It can be moved in three different axes, controlling the cut-off wheel and both the X- and Y-table. The multifunction knob is used for setting all cutting parameters, and can be operated even with heavy-duty working gloves.

With the automatic X-table, great possibilities open. Axitom cutting machines, equipped with the automatic X-table, have a total of four Multi-Cut modes available, which enables you to do serial sectioning without repositioning your workpiece. The automatic Y-table is for extra-deep workpieces and extra-large specimens using the AxioCut cutting mode.

ExciCut mode is an oscillating movement of the cut-off wheel to reduce the contact area with the workpiece and minimize the risk of thermal damage. In this way you can section very hard materials with better results and a better lifetime of the cut-off wheel.

AxioCut Step is a movement of both the automatic Y-table and the cut-off wheel to enhance the cutting capacity. The table has a movement of 150 mm (5.9”), and the possible sample size to be sectioned is thus increased by the same amount. This means that Axitom-5/400 can handle workpieces up to 125 x 290 mm / 4.9” x 11.4” and Axitom-5 can handle workpieces up to 110 x 245 mm / 4.3” x 9.6. The cut-off wheel moves up and down the sample, minimizing the contact area, and avoiding overheating and thermal damage.

Maintenance and cleaning can be some of the most time-consuming elements of the cutting process, but not with the Axitom cutting machine. AxioWash is Struers’ patented cleaning program that automatically cleans the inside of the machine, and afterwards, you only need to clean the horizontal surfaces inside the chamber. That’s it - the machine is now ready for the following day. When AxioWash is used every day, only a minimum of effort is needed.

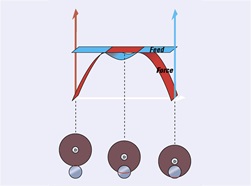

Struers has developed OptiFeed intelligent feed control to eliminate the risk of damaging your workpiece, the cut-off wheel, or the motor when sectioning materials with varying properties which require different feed speed settings. With the help from OptiFeed, Axitom continuously measures the load on the cutting arm. The pre-set feed and force values are maximum values, and when the machine detects force exceeding the pre-set force limit, it will automatically decrease the feed speed to protect the workpiece, cut-off wheel, and equipment. The speed is automatically adjusted up and down to aim for a force as close to the limit as possible. The feed is thereby constantly optimized without sacrificing the quality of the cut or good wheel economy, and you get the fastest possible cut.

Save setup time by storing cutting sequences for reoccurring workpieces, ensuring that your samples are ideal for the next step in your preparation process. Choose from four different serial cutting modes to do your serial sectioning exactly as you want.

Intuitive user interface combined with the easy to use multifunction knob and positioning of the three axes with the joystick, makes the machine programming fast and ensures a precise setup of cutting sequences.

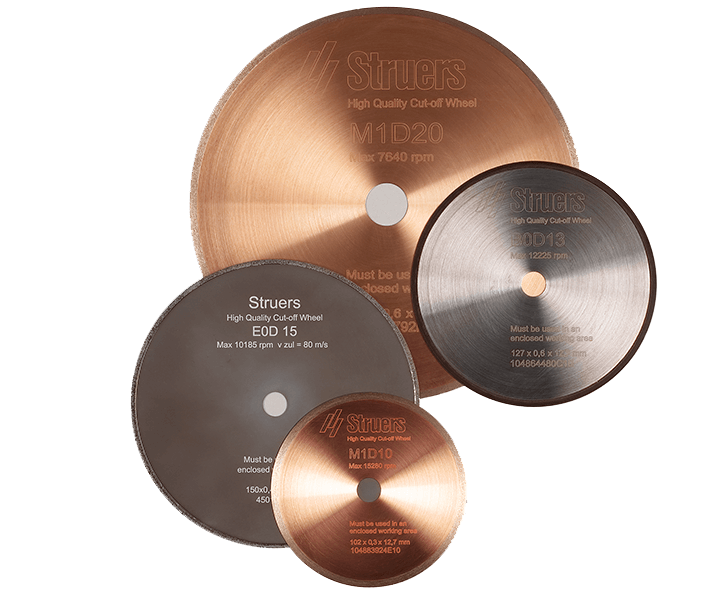

Choose the Axitom model with the right cut-off wheel size to fit your exact needs. Depending on the size of your workpieces, choose the Axitom model with cut-off wheel size giving the right capacity for your application. See the bottom of this page for the different Axitom models.

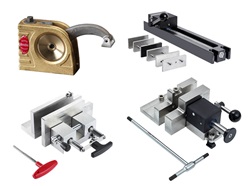

Choose from a wide range of versatile 12 mm T-slot clamping tools. Enjoy the easy clamping of different geometries with the use of Struers quick clamps or vertical clamps. A wide range of support tools are available for more advanced geometries. See the Axitom brochure for the full selection.

You can program Axitom to stop automatically when it registers that the workpiece is cut through. This saves you time as it ensures that the cut is always followed through completely.

Axitom is available in two versions.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

A short and clear description that gives you an immediate overview to assist you in making the best choice of equipment.

• Capacity and performance specifications

• Dimensions and weight

• Electrical data

• Noise levels

• Safety

Get the full introduction, descriptive visuals, and key feature descriptions to assist you in deciding on your choice of equipment.

• Explanatory photos

• Key feature descriptions

• Technical Data Sheet

As the only cut-off machine in its field, Magnutom-5000 can map out the most complex of section sequences and simulate all individ...

Discotom-10 and Discotom-100 are versatile tabletop cut-off machines, designed to give you a cost-efficient opportunity to expand ...

The robust design of Labotom-5 and Labotom-15 manual cut-off machines means they are suitable for use both in the lab and in the p...

Extremely hard ferrous metal (500 < HV < 1400).

Very hard ferrous metal (400 < HV < 800).

Hard Ferrous metal (275 < HV < 750).

Medium hard ferrous metal (200 < HV < 550).

Medium soft ferrous metal (100 < HV < 500).

Soft ferrous metal (75 < HV < 375).

For materials with HV 500-2400.

For materials with HV 500-2400.

For recirculation, cooling and cleaning.

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor

We have been using Struers equipment and consumables for almost 30 years and have benefitted enormously from their unparalleled service and applications support.John Crane UK Ltd. UK Bill Taylor Materials & Forensics Engineer