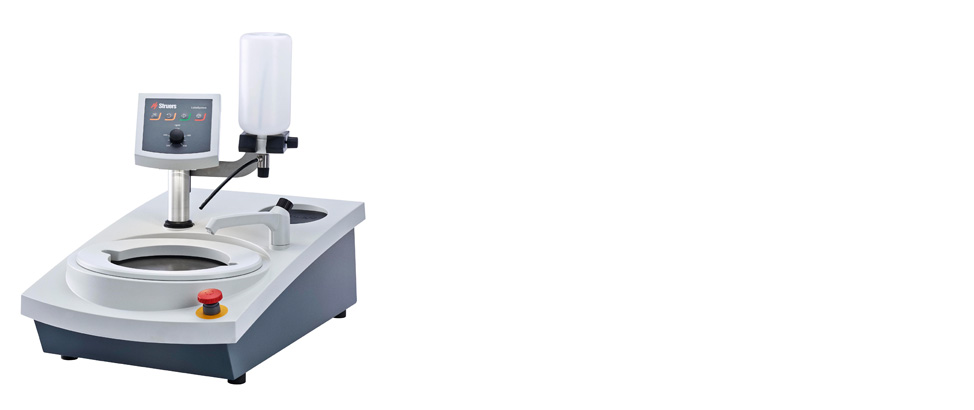

LaboSystem facts

- Fast and reliable specimen preparation

- Short process time and small footprint

- Manual or semi-automatic grinding and polishing

- Flexible working stations

- Cone Disc System

- Fast to set up and easy to use

- Modular system, adaptable for your changing needs

LaboSystem is ideal if you need a durable grinding and polishing solution that is quick to set up and use – and fast enough to keep up with throughput demands. An adaptable modular system with a small footprint, LaboSystem can change with your needs – you can use it as a manual station or with additional semi-automatic add-ons. Its large disc helps optimize specimen preparation time.

Higher throughput and efficiency

LaboSystem is designed for reliable and fast manual and semi-automatic grinding and polishing in the lab or next to the production line – and it has the endurance and speed needed to keep up with high throughput.

As a manual or semi-automatic solution, LaboSystem can adapt to your lab’s needs and throughput demands. And, if you need to increase throughput, you can use two stations in a single system or multiple systems in parallel.

Speed up your process

For a faster process, you can run a 300 mm (12’’) diameter disc. This results in a 44% increase in surface area compared to a 250 mm (10’’) disc, giving you faster and more efficient grinding and polishing. Maintenance is also faster due to the unique Cone Disc System, while the special bowl liner makes cleaning quick and simple.

LaboSystem is also easy to learn. Operators with no previous experience can get up to speed quickly – enabling you to begin processing specimens right away, with little or no setup time.

Adaptable for your changing needs

LaboSystem’s modular design ensures your needs will be met as they evolve over time. For example, you can upgrade your manual LaboPol machine to a semi-automatic grinding and polishing solution with the addition of a LaboForce specimen mover and an automatic LaboDoser.

The LaboSystem includes a choice of three LaboPol grinding/polishing machines, three LaboForce specimen movers, and two LaboDoser dosing units. This gives you seven robust combinations – all proven to perform in demanding production environments.

KEY FEATURES THAT ENABLE FAST, RELIABLE, AND ADAPTABLE MANUAL GRINDING AND POLISHING

-

High reliability for continual operation

LaboSystem has undergone more than 40,000 cycles of durability testing and has been subject to six months of field tests in Germany, the USA, the Czech Republic, and Norway. As a result, you know it has the endurance and speed needed to keep up with high throughput.

High reliability for continual operation

-

Cone Disk System for faster cleaning

The Cone Disc System enables you to save time with extremely fast disc removal prior to cleaning. In addition, the high mass of the cone disk ensures a lower preparation temperature, reducing your consumption of consumables.

Cone Disk System for faster cleaning

-

Elliptical splash ring and bowl for faster preparation

The elliptical splash ring and bowl will save you time by making it easy to prepare the disk for the next preparation step.

Elliptical splash ring and bowl for faster preparation

-

High durability for long-term performance

Thanks to its highly durable design, the LaboSystem can be used in even the most demanding production environments. It is made from corrosion-resistant and impact-proof materials and has been extensively field tested in four different countries.

High durability for long-term performance

-

Bowl liner for faster cleaning

Save time and effort with the bowl liner, which comes as standard on all LaboPols. When the machine has to be cleaned, the bowl liner can easily be removed – and either cleaned or discarded.

Bowl liner for faster cleaning

-

Longer machine lifetime with ‘soft start’

LaboPol grinding/polishing machines always begin with a ‘soft start’ to reduce wear and extend the service life of the machine.

Longer machine lifetime with ‘soft start’

-

Control panel protection for greater reliability

The elevated control panel will remain free from water splashes and avoid damage from heavy or loose specimens. Its elevated position also reduces the chance of accidentally changing the rpm setting during operation.

Control panel protection for greater reliability

-

Operator safety

LaboSystem has been designed with operator safety in mind. When pressed, the emergency button immediately stops all moving parts. In addition, the small gap between the splash ring and bowl prevents injury to fingers.

Operator safety

-

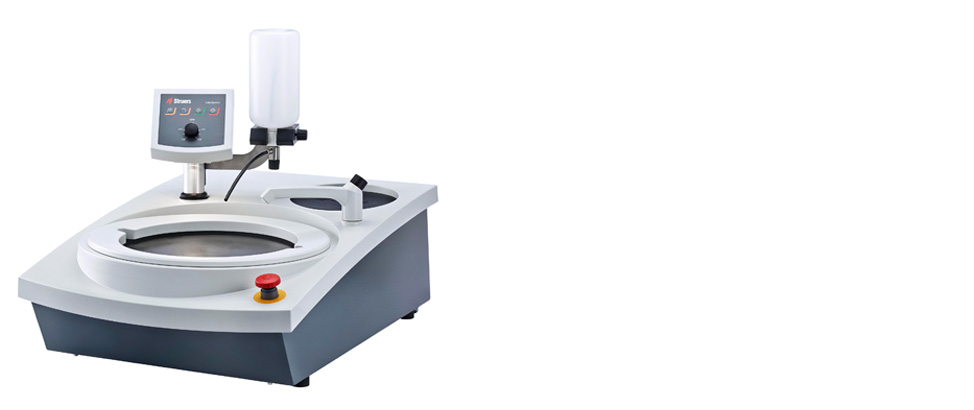

Convenient storage for a smaller footprint

LaboSystem’s storage pad can be used to keep items, such as unused specimen mover plates, tidy and within easy reach when needed.

Convenient storage for a smaller footprint

-

Adaptable for changing needs

Thanks to LaboSystem’s modular and flexible design, it can be adapted to suit the evolving needs of your working environment. It offers a choice of three LaboPol grinding/polishing machines, three LaboForce specimen movers, and two LaboDoser dosing units. This gives you seven robust combinations – all proven to perform in demanding production environments.

Adaptable for changing needs

Facts

Model types

LaboSystem is available in many variations, see specifications for details.

LaboPol-20:

Grinding/polishing machine with variable speed (50-500 rpm) for 200 mm dia. disk. Supplied with manual splash guard and bowl liner. LaboUI control panel and disks are ordered separately. Specimen mover LaboForce-50 can be mounted.

LaboPol-30:

Grinding/polishing machine with variable speed (50-500 rpm) for 230, 250, or 300 mm dia. disk. Supplied with manual splash guard and bowl liner. LaboUI control panel and disks are ordered separately. Specimen mover LaboForce-50/-100/Mi can be mounted.

LaboPol-60:

Grinding/polishing machine with variable speed (50-500 rpm) for two disks, 250 or 300 mm dia. Each disk with automatic water valve, manual splash guard, and bowl liner. LaboUI control panel and disks are ordered separately. One specimen mover LaboForce-50/-100 can be mounted.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Technical Data

LaboSystem Technical Data Sheet

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download Technical Data SheetGet your brochure for LaboSystem

Download our LaboSystem brochure to get a full overview of these grinding & polishing equipment.

Download the brochureFind the right accessories for your LaboSystem

Increase the efficiency of your process and improve the reliability of your result with our grinding and polishing accessories. We offer a full range of specimen holders, mover plates, leveling devices, and preparation discs.

Download our accessories overview sheetGrinding & Polishing consumables

-

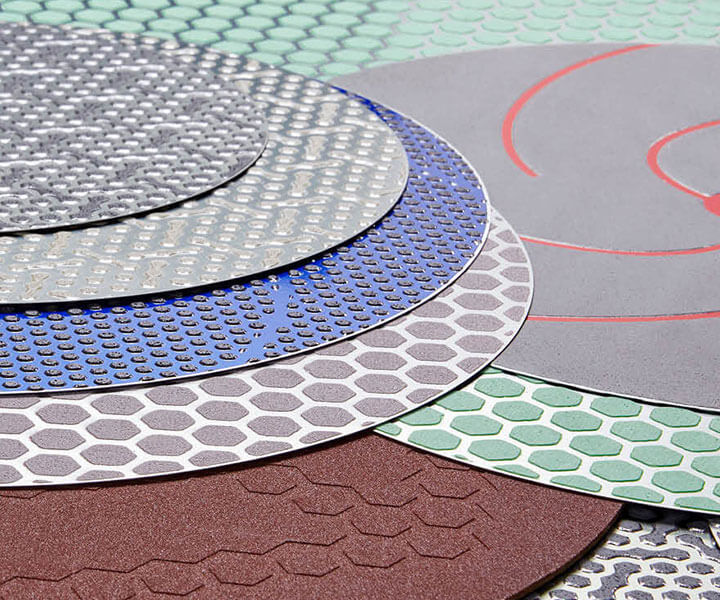

MD Grinding

For plane and fine grinding with virtually no artifacts

Read more Contact sales -

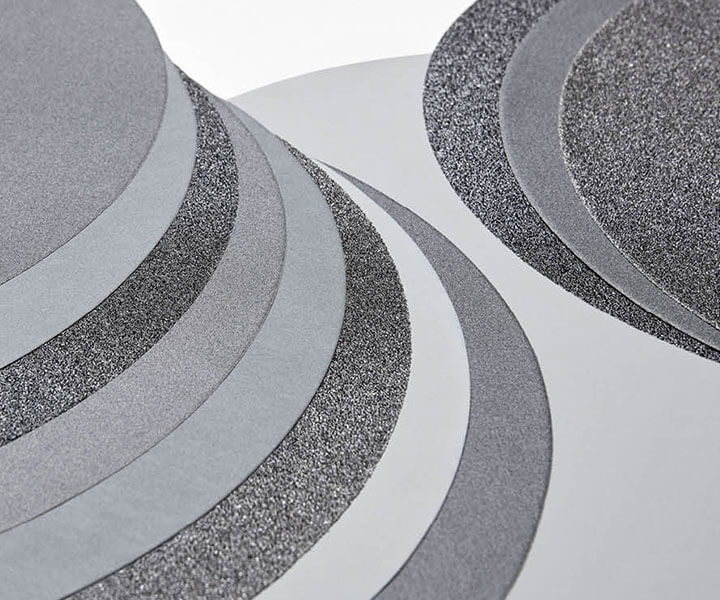

Silicon Carbide Foil and Paper

For plane and fine grinding

Read more Contact sales -

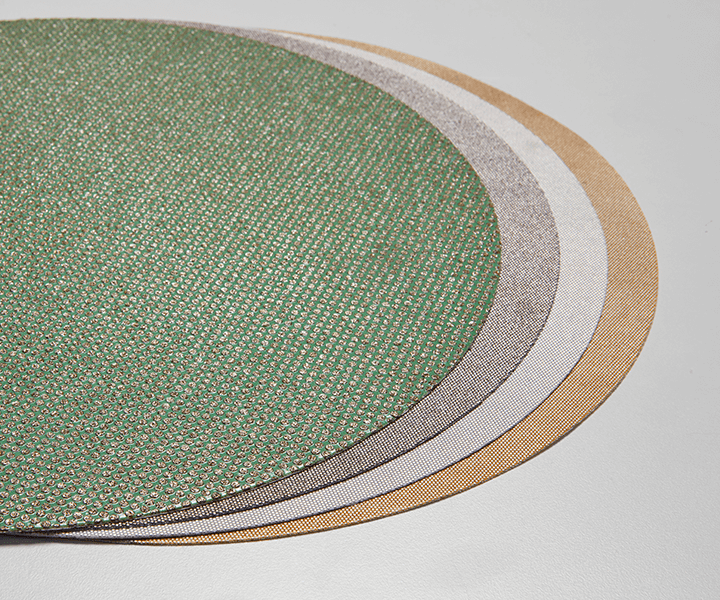

Diamond Pads

For plane and fine grinding of very hard materials

Read more Contact sales -

Polishing cloths

For any material and preparation goal

Read more Contact sales -

DiaPro

All-in-one diamond solution optimized for a specific polishing cloth

Read more Contact sales -

DiaDuo-2

All-in-one diamond solution

Read more Contact sales -

DP-Products

Diamond suspensions in a wide variety of grain sizes and formats

Read more Contact sales -

DP-Lubricants

For accurate cooling and lubrication while polishing

Read more Contact sales -

Oxide Polishing

When no scratches and deformation is required

Read more Contact sales -

+

-

−

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

We have always experienced extremely repeatable and consistent, high-quality results. The consistency and reliability of our Struers cutting machines was instrumental in our decision to install a similar Struers system in our plant in Indonesia.Grinding Media, Moly-Cop (Australia) Glenn Sullivan Technical Developments Manager

We have been using Struers equipment and consumables for almost 30 years and have benefitted enormously from their unparalleled service and applications support.John Crane UK Ltd. UK Bill Taylor Materials & Forensics Engineer