Labotom

- Cutting capacity: 62 x 250 mm / 2.5" x 9.8"

- Manual machine with simple 3-button control panel

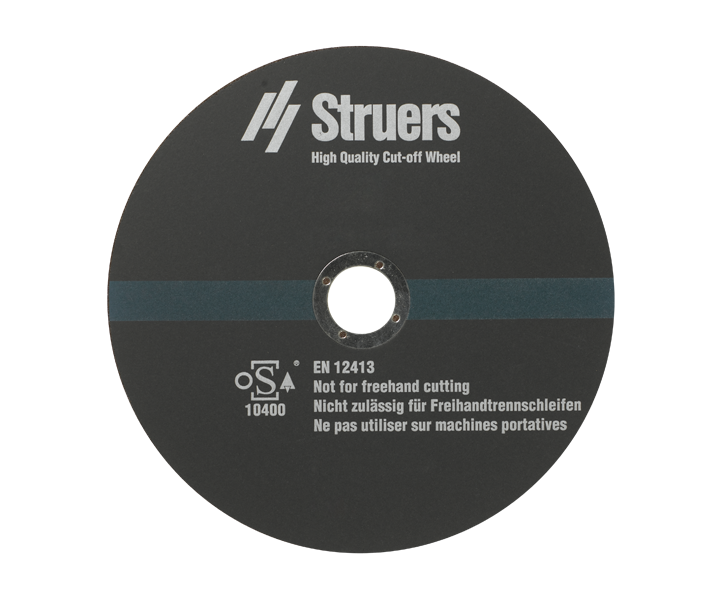

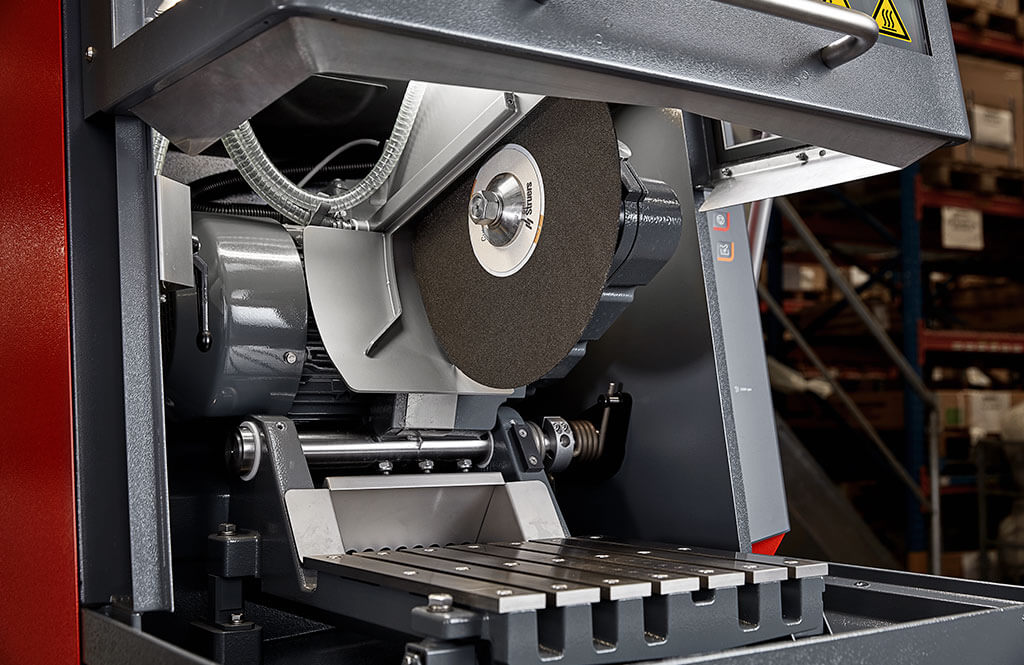

- Cut-off wheel size 250 mm or 350 mm / 10.0” or 14.0” dia.

- Large cutting table

- Smooth movement cutting handle for controlled sectioning

- Integrated flushing gun

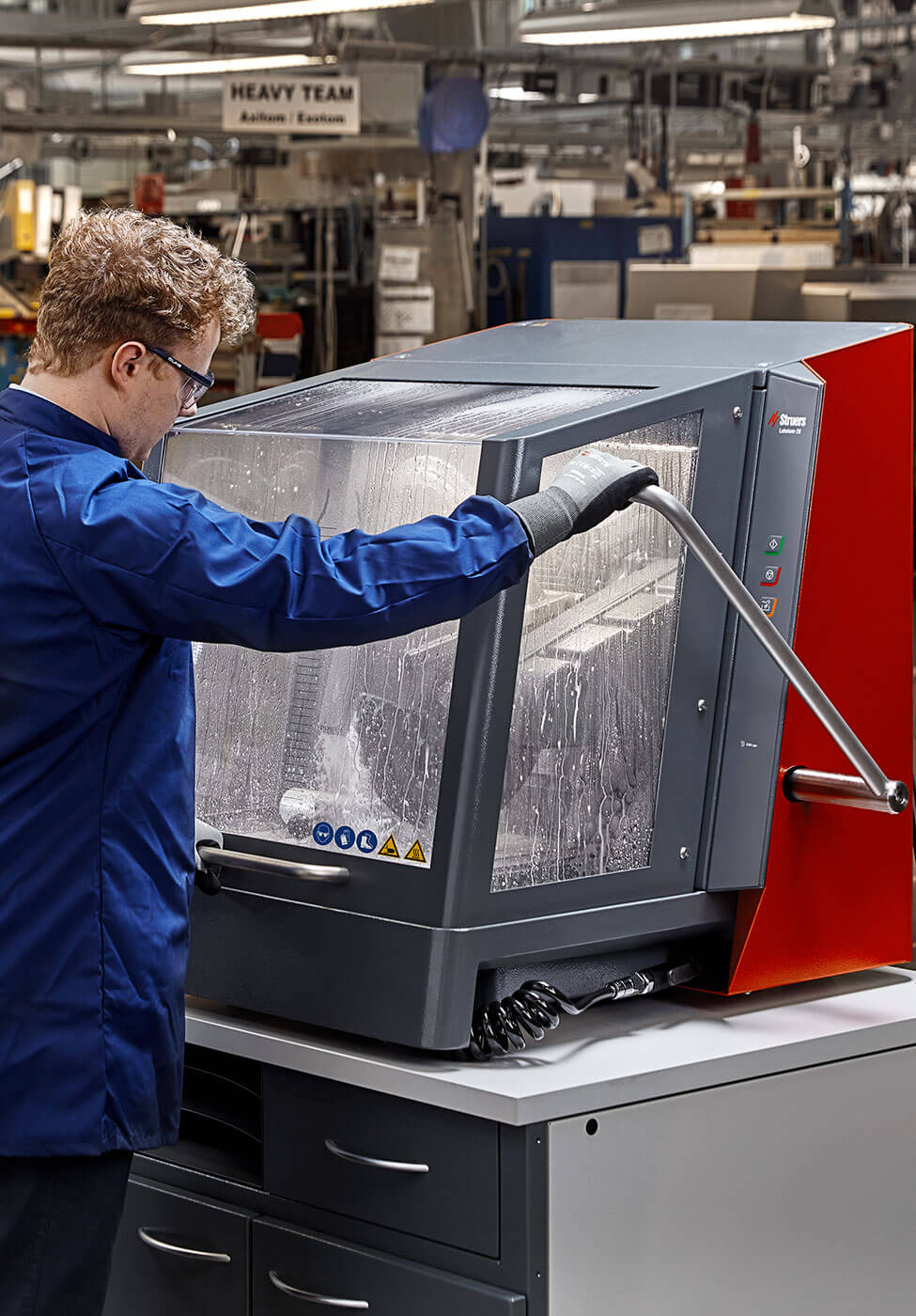

Labotom is a simple-to-use and powerful table-top cutting machine that can handle a wide range of workpiece shapes, sizes, complexities and materials. Sturdy and reliable, it ensures maximum uptime and can be used by any operator to section workpieces quickly and efficiently, with minimal training. The fixed cooling nozzles improves cutting quality and reduces the risk of operator error.

Optimize process time with highly efficient setup and operation

A fast and efficient specimen analysis process starts with the sectioning. With Labotom, any operator can section workpieces quickly and efficiently, to help optimize your inspection process.

Setting up a cut is fast and simple. No programming is required and there are just three buttons: Start, Stop and Flush. To further increase efficiency, Labotom’s large cutting table has 10 mm T-slots for flexible clamping and the fixed cooling nozzle eliminates the need to place nozzles manually.

Experience high flexibility with one solution for different workpieces

Labotom may be the only cutting machine you ever need. The large cutting table and versatile cut-off wheel can handle a wide range of workpieces – of different shapes, sizes, complexities and materials. For very long workpieces, the machine has extension tunnel options.

Find your Labotom-20 consumables here >

Find your clamping tool here >

Minimize downtime with integrated cleaning

Cleaning can be one of the most time-consuming parts of the cutting process. Not with Labotom. To minimize cleaning time, Labotom includes an integrated flushing gun and big drain. This means any debris is quickly and easily washed away.

KEY FEATURES THAT ENABLE QUALITY CUTTING IN THE LAB OR PRODUCTION HALL

-

Simple operating panel

No programming is required and there are just three buttons: Start, Stop and Flush.

Simple operating panel

-

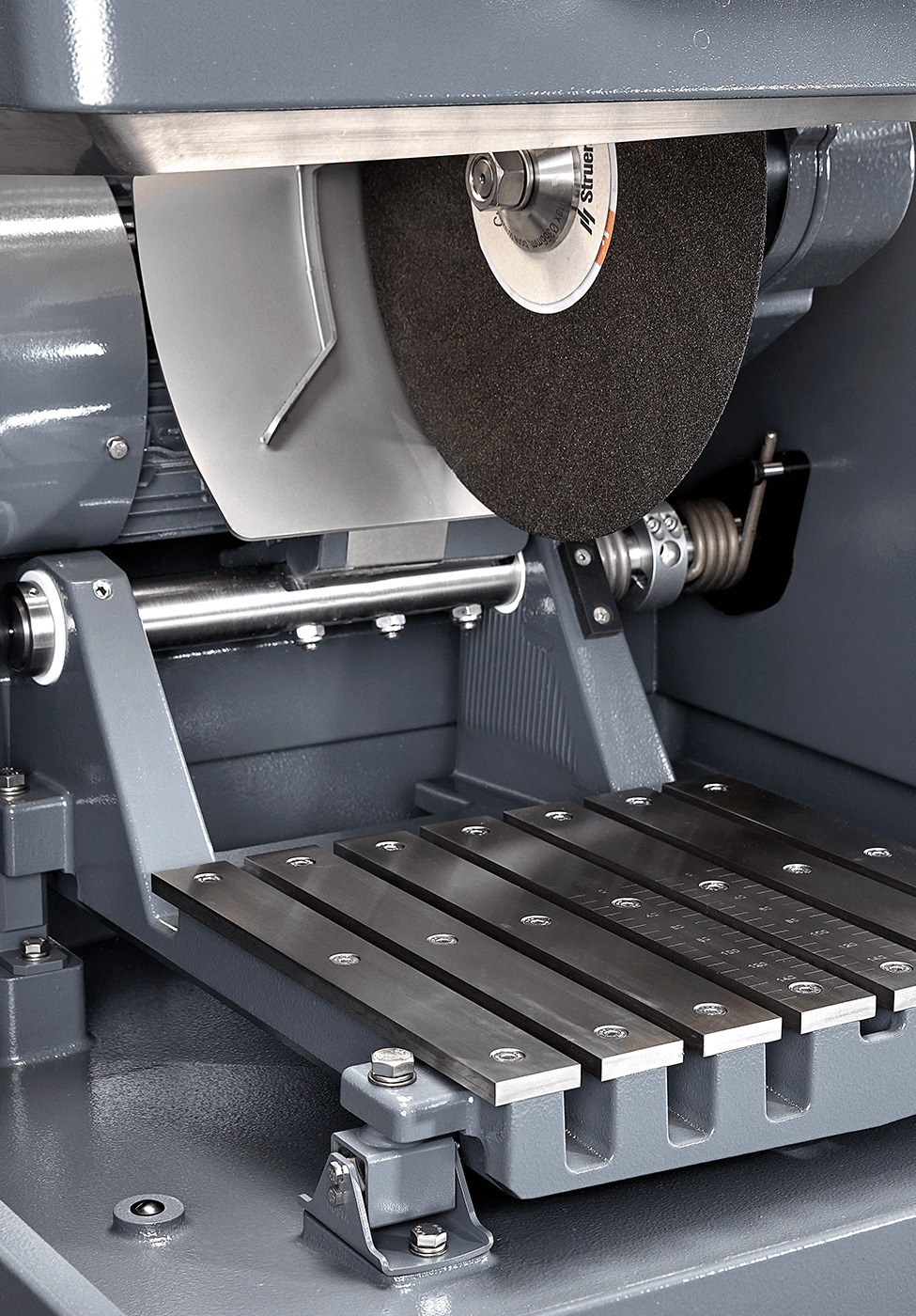

Large cutting table for fast alignment

The large cutting table and safety guard enable you to access the cutting table from three sides, so you can position and maneuver large or odd-sized workpieces with ease. The work area is illuminated with a LED light for better visibility when working.

Large cutting table for fast alignment

-

Optional extension tunnel for long workpieces

With extension tunnel options, you can section workpieces of any length.

Optional extension tunnel for long workpieces

-

10 mm T-slots for flexible clamping

The large cutting table has 10 mm T-slots. These work perfectly with Struers’ range of clamping tools for fast clamping of any workpiece, including small, large or odd-shaped workpieces.

10 mm T-slots for flexible clamping

-

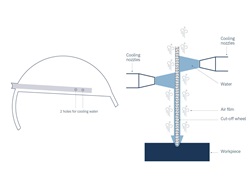

Cooling nozzle reduces the risk of burns

The advanced design of the fixed cooling nozzle ensures optimal cooling, even as the cut-off wheel becomes smaller through use, which reduces the risk of burns.

Cooling nozzle reduces the risk of burns

-

Cutting handle designed for greater control

The smooth movement of the cutting handle gives greater control during sectioning.

Cutting handle designed for greater control

-

Adjustable flushing gun for faster cleaning

The integrated and adjustable flushing gun makes it easy to clean between cuts. There is a big drain with a smooth sloped surface to ensure it is easy to wash debris away.

Adjustable flushing gun for faster cleaning

-

Durable design for less maintenance

The base of the machine is made of cast aluminum to ensure maximum durability and a long lifetime.

Durable design for less maintenance

-

Specimen collector (Labotom-20 only)

To further increase efficiency, the specimen collector catches the cut specimens, so the operator does not spend time trying to find them.

Specimen collector (Labotom-20 only)

-

Guiding lines for higher speed and quality (Labotom-20 only)

Guiding lines on the cutting table make workpiece alignment fast and simple. There are also guiding lines on the safety guard to enable better operator control during sectioning.

Guiding lines for higher speed and quality (Labotom-20 only)

-

Laser preview for fewer errors (Labotom-20 only)

Prior to cutting, the integrated laser previews each cut, reducing the risk of operator error.

Laser preview for fewer errors (Labotom-20 only)

-

Ergonomic safety guard for better operator health (Labotom-20 only)

The ergonomic sliding safety guard ensures the correct movement when closing and opening, with arms close to the body.

Ergonomic safety guard for better operator health (Labotom-20 only)

-

AxioWash integrated cleaning (Labotom-20 only)

AxioWash is an integrated cleaning program that cleans the inside of the machine. Afterwards, you only need to clean the horizontal surfaces inside the chamber.

AxioWash integrated cleaning (Labotom-20 only)

Facts

Model types

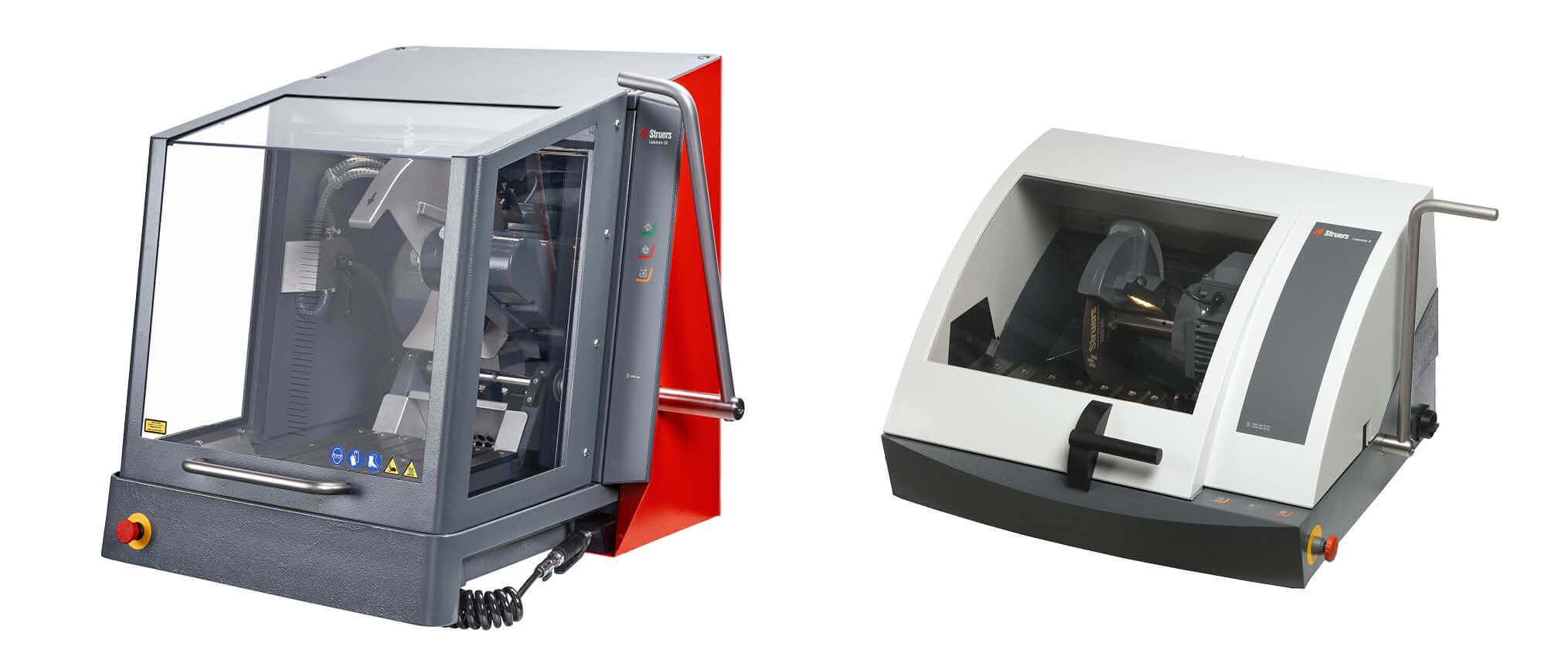

Labotom is available in two variations, see specifications for details.

Labotom-20

Labotom-20 is ideal for fast manual cutting of large workpieces (up to 65 x 250 mm / 2.5” x 9.8”) and is able to handle a wide variety of shapes, sizes, complexities and materials. It also includes special features to improve the quality of each cut.Features include guiding lines, line laser, specimen collector, tunnel options on both sides, 10 mm T-slots, LED strip light, automatic cooling nozzle, sliding safety guard, adjustable flushing gun and AxioWash integrated cleaning.

Labotom-5

Labotom-5 is ideal for fast manual cutting of smaller workpieces (42 x 120 mm / 1.7” x 4,7”) and is able to handle a wide variety of shapes, sizes, complexities and materials.Features include simple control panel, tunnel option on one side, LED light, 10 mm T-slots, big cutting table and adjustable flushing gun.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Get Your Technical Data Sheet for Labotom

A short and clear description that gives you an immediate overview to help you make the best choice of equipment.

• Capacity and performance specifications

• Dimensions and weight

• Electrical data

• Noice levels

• Safety

Get Your Brochure for Labotom

Get the full introduction, descriptive visuals, and key feature descriptions to help you qualify your choice of equipment.

• Explanatory photos

• Key feature descriptions

Get Your Deep Dive for Labotom

Open Deep DiveCutting consumables

-

Abrasive cut-off wheels

Extremely hard ferrous metal (500 < HV < 1400).

Go to webshop Contact sales -

Abrasive cut-off wheels

Very hard ferrous metal (400 < HV < 800).

Go to webshop Contact sales -

Abrasive cut-off wheels

Hard Ferrous metal (275 < HV < 750).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium hard ferrous metal (200 < HV < 550).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium soft ferrous metal (100 < HV < 500).

Go to webshop Contact sales -

Abrasive cut-off wheels

Soft ferrous metal (75 < HV < 375).

Go to webshop Contact sales -

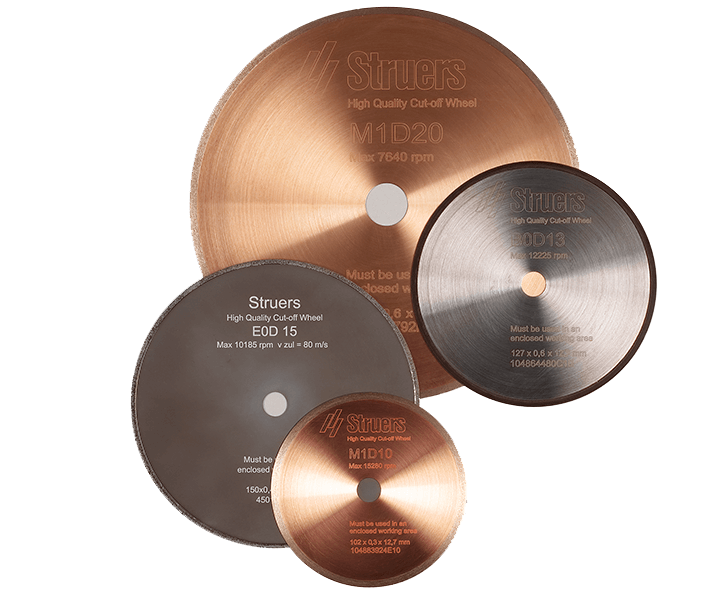

Diamond cut-off wheels

For materials with HV 500-2400.

Go to webshop Contact sales -

CBN cut-off wheels

For materials with HV 500-2400.

Go to webshop -

Additives for cutting

For recirculation, cooling and cleaning.

Go to webshop Contact sales -

+

-

−

Related products

Axitom

- Cutting capacity 125 x 290 mm / 5.0" x 11.5"

- Fully automatic high volume cutting machine

- Cut-off wheel size 350 or 400 mm / 14.0” or 16.0” dia.

If you visit some of the largest automotive materialographic facilities around the world, there is a good chance that you will com...

Discotom-100/-10

- OptiFeed – intelligent feed control

- AxioWash* (Automatic cleaning)

- ExciCut for very hard materials

Discotom-10 and Discotom-100 are versatile tabletop cut-off machines, designed to give you a cost-efficient opportunity to expand ...

Secotom

- Cutting capacity 50 x 165 mm.

- Automatic precision cutting machine

- Cut-off wheel size 75 – 203 mm/ 3- 8” dia.

Advanced precision cutting machine with large capacity and application flexibility

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer